The Dubai Electricity and Water Authority (DEWA) and GE conducted a joint workshop on 3D printing and additive manufacturing. This was done as part of DEWA’s vision to be a sustainable innovative world-class utility and strengthen the efficiency of electricity generation, distribution and transmission. The workshop followed the signing of a Memorandum of Understanding (MoU) signed between the two entities earlier this year to collaborate on 3D printing, additive manufacturing and digital technologies.

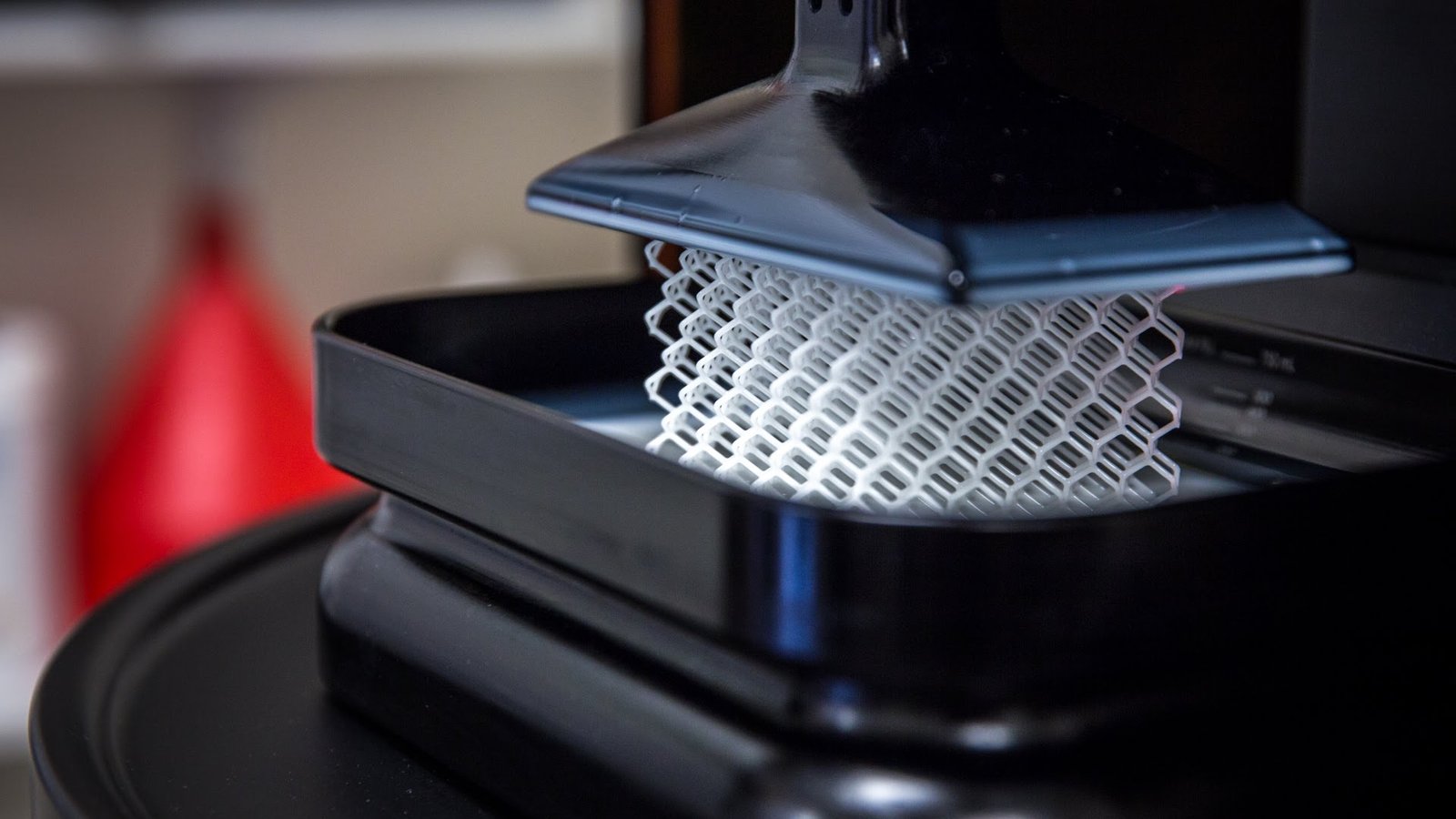

The workshop focused on 3D printing applications for the utility sector with experts from both entities sharing their experiences and learning. This was followed by breakout sessions where senior officials of the two entities discussed how additive technology applications can enable DEWA to optimize its supply chain, as well as reduce operations & maintenance delays, unplanned outages, and the cost of spares.

The brainstorming session also identified the opportunities and challenges in 3D printing for the utilities sector, with the outcomes of the workshop to be leveraged for the practical implementation of digital solutions. While DEWA highlighted the application of 3D printing with relation to the entity, GE presented its global success stories and its applications in the region.

HE Saeed Mohammed Al Tayer, MD & CEO of of DEWA, said: “At DEWA, we are committed to achieving our goal of being a sustainable innovative world-class utility in line with the vision of HH Sheikh Mohammed bin Rashid Al Maktoum, UAE Vice President and Prime Minister and Ruler of Dubai. By leveraging 3D printing and additive manufacturing, we are setting a first for the utilities sector in the region, and the successful prototypes we create, in collaboration with GE Additive, will serve as a benchmark for the industry globally.”

Dr. Dalya Al Muthanna, President & CEO of GE Gulf, added: “The first workshop, following our MoU with DEWA, has been a great learning experience for both entities, as we discussed the practical implementation of additive manufacturing and 3D printing for the utilities sector. Additive manufacturing is a remarkable opportunity to drive operational efficiency and productivity, and our partnership with DEWA will help co-create 3D printing technologies relevant to the region, and support Dubai’s vision to be a hub for 3D printing.”

GE Additive’s MoU with DEWA marks a first-of-its-kind partnership by the company in the region with a utility provider. As per the MoU, DEWA’s R&D Center and Innovation and The Future Division will work closely with GE on embracing and encouraging disruptive innovation, and accelerating promising startups in new areas shaping the future of industry.

Additive manufacturing is a key part of GE’s evolution as a digital industrial company. The company also invests around US$500 million annually in advanced manufacturing and materials science at the its Global Research Center, which has developed additive applications across six GE businesses, created new services applications across the company, and earned 346 patents in materials science.